YMF provides a full suite of advanced instruments for microfabrication at multiple lab locations.

Location: Petrie Building RM423

Photolithography

OAI Model 800E Enhanced Mask Aligner

Capabilities and Features:

- Dual 1 MP resolution GigE CCD cameras with continuous zoom optics for better alignment accuracy

- Objective separation 44-200mm

- Optical magnification 70x – 400x

- Large optics Y travel for flat alignment

- Enhanced digital image capture and blended image overlay resulting in better front to backside overlay accuracy

- Computer controlled illumination for more repeatable alignment

- Auto-alignment utilizing the latest pattern recognition technology from Cognex

- Includes CD Measurement capability

- Backside alignment with optical backside magnification 180x, digital zoom and motorized auto-focus

- Auto Wedge Effect compensation including 3 pt wedge- effect leveling and automated gap setting

- Joystick control of alignment tooling and optics

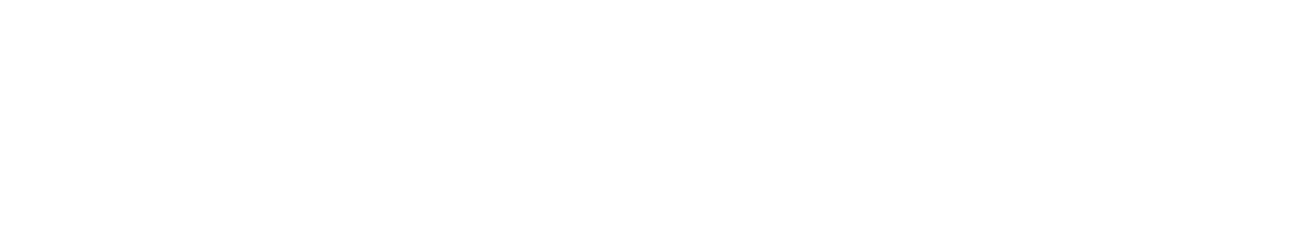

Spin Coater

Capabilities and Features:

- FEP Teflon® chamber liner

- 12.5" (318 mm) I.D. bowl-shaped process chamber

- Up to Ø8" (Ø200 mm) wafer or 7" (178 mm) square substrate capability

- Speed: to 12K RPM, Acceleration: up to 13K RPM (in 1 RPM increments)

- Time: 1 second to 99 minutes 59.9 seconds in 0.1 second increments

- Vacuum chuck — Ø100mm (Ø3.9") for Ø100mm through Ø200mm substrates

- Micro Fragment Adapter for 3mm - 10mm Fragments

- Mid Size Fragment Adapter for 5mm - 25mm Fragments

- Alignment Tool for 125 mm, 150 mm, and 200 mm SEMI wafers

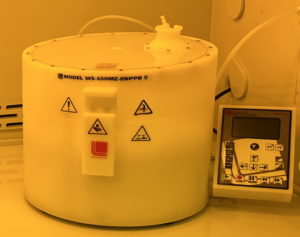

Hot Plate

Capabilities and Features:

- 8’’x8’’ surface area

- Up to 450oC

- Each program can be 10 steps

- Repeat any program 1–98 times automatically. Infinite repeats settable

- Programmable and non-programmable operation

- Platinum RTD temperature measurement for ±1% accuracy

- Temperature ramping for exact heating and cooling rates

- PID temperature control to 1°C on plate surface or solution with accessory probe

- Stir up to 2 liters of aqueous solutions from 100–1500 rpm (HS40 and HS40A)

- Timer goes up to 99 hours, 59 minutes, 59 seconds with user settable Auto-Off

Ashing and Cleaning

Plasma Etch PE-50 XL

Capabilities and Features:

- 400W 50KHz Continuously Variable Power Supply

- Two 0-25cc/min Rotometers with Precision Needle Valves

- Stores One Recipe for Automatic Process Sequencing

- Chamber is made of 6061-T6 Aluminum

- Chamber size is 7.5”Wx8.75”Dx3.5”H

Ultrasonic Cleaner

Capabilities and Features:

- 7L volume (30L x 15W x 15D cm)

- Frequency : 35kHz +3.5/-5

Characterisation and Metrology

KLA-Tencor Alpha-Step D600 Contact Profilometer

Capabilities and Features:

- 200 mm motorized stage

- 150 mm x 178 mm X-Y range of motion

- Highest vertical range at 1200 μm

- Low force measurements at 0.03 to 15 mg

- Step height repeatability of 5 Å on a 1 μm step

- High resolution 5 MP color camera with 4x digital zoom

- Software features: Keystone correction, arc correction, sequencing with deskew, and automated stitching

Optical Microscope

Other

Wet Processing Benches

-

180cm wide operation space

- UV free environment

- Integrated facilities (DI water, N2 and CDA)

- Exhausted and laminar flow working environment

-

Better than ISO 5 (CLASS 100) conditions in the working space

Location: Bergeron Building RM037

Dry Etching

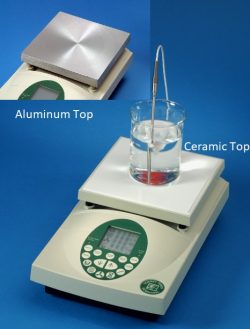

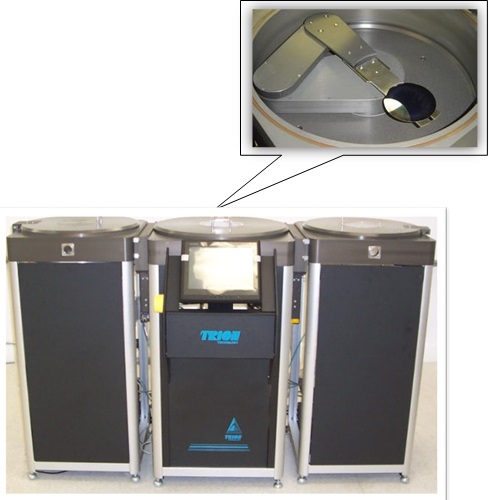

Trion Technology Minilock – Phantom Duo (RIE)

Capabilities and Features:

- Vacuum loadlocked system with compatible robotic arm

- Including an ICP source for improved efficiency

- 600W, 13.56MHz RF generator

- Substrate biasing

- Fully programmable and automated process

- Auto and manual tuning of the RF matching network

- Seamless transfer to PECVD chamber without losing vacuum

Chemical and Physical Vapour Deposition

Trion Technology Minilock – Phantom Duo (PECVD)

Capabilities and Features:

- Vacuum loadlocked system with compatible robotic arm

- 300 W, 350kHz power supply

- Fully programmable and automated process

- Electrode heating

- Seamless transfer to RIE chamber without losing vacuum

Angstrom Engineering Amod Sputter System

Deposition Sources : with its 500mm x 500mm baseplate, it could accommodate up 6 sources and a wide variety of PVD processes with the chamber height of 500mm

Sputtering : RF, DC, and reactive sputtering available

Substrate Fixturing and Masking:

- Vacuum Control - can be configured for high vaccum (HV) or ultra-high vaccum (UHV) utilizing a turbo pump.

- Heated, Cooled, & Biased Stages - LN2/GN2 cooling to -170° C, Heating to 900° V, Auto-calibration via AERES software, RF or DC stage biasing

Angstrom Engineering Nexdep Ebeam Evaporator

Deposition Sources : with its 400mm x 400mm baseplate, it could accommodate up 6 sources and a wide variety of PVD processes with the chamber height of 500mm

Electron Beam Evaporation : Wide range of source options, Programmable sweep controller with recipe storage, Torque sensing crucible indexer detects pocket jams.

Substrate Fixturing and Masking:

- Vacuum Control - can be configured for high vaccum (HV) or ultra-high vaccum (UHV) utilizing a turbo pump.

- Variable Angle Stages - comfortably coat 3D features, create complex Nano-structures -95° to 95° tilt with continuous rotation

- Heated, Cooled, & Biased Stages - LN2/GN2 cooling to -170° C, Heating to 900° V, Auto-calibration via AERES software, RF or DC stage biasing

- Planetary & Dome Fixturing - domed substrate carrier for lift-off and batch process, Planetary motion & flip fixturing are available

Other

Laser Plotter and Development Processor

The compact RP325+LXT line. 660 x 660 mm - 26” x 26”

Capabilities and Features of Laser Plotter :

- Data input formats: RS274D, RS274X, DPF and EIE RPL.

- Plot queues can be setup with more than 15 different plot parameters.

- Temperature and humidity recorded for each plot

- Compatible with most film processors

- Overall accuracy of ± 10 µm (± 0.4 mil) and repeatability of (± 3 µm (± 0.12 mil)

Exposing unit for the Laser Plotter :

- Max Exposure area : 660 x 660 mm (26“ x 26“)

- Compatible film lengths: 18“, 20“, 24“, 25.5“ and 26“

- Compatible film width : Any width larger than 300 mm (12“) up to 520 mm (20,5’’)

- Film thickness : 0.18 mm (7 mils)

- Exposure device: One 512 beam SDH3 head with light intensity equalization

- Light Wavelength : Monochromatic red light, 647 nm

The Hope/Carnfeldt EG 750 PCB processor

Capabilities and Features of Development Processor :

- Inlet width : 75 cm/ 29''

- Rack length dev. : 32 cm / 12.6"

- Developing time min.-max. : 20 – 80 sec.

- Speed at 30 sec. dev. time : 64 cm/min.

- Max. film length : 5 m / 16.4 ft.

- Min. film size : 18 x 10 cm / 7 x 4"

- Dev./fix./wash temperature range : 20 - 45°C / 68 – 113°F .

Keyence VHX-970F Digital Microscope

Location: Bergeron Building RM324

Capabilities and Features of Keyence VHX-970F Digital Microscope :

- 20x – 2000x magnification

- Bright Field, Dark Field, Polarized, Mixed Lighting

- Motorized z-stage (49 mm movement range)

- Auto-focus

- 3D profiling